As one of the most common fasteners, the shape of the bolt's head plays a crucial role in various application scenarios. Whether in the assembly of mechanical equipment or the fixation of building structures, the selection of bolt heads is directly related to the stability, usage effect and safety of the connection. Common bolt head shapes include cylindrical heads, flat round heads, disc heads and countersunk heads, etc.

Jiangxin Fasteners

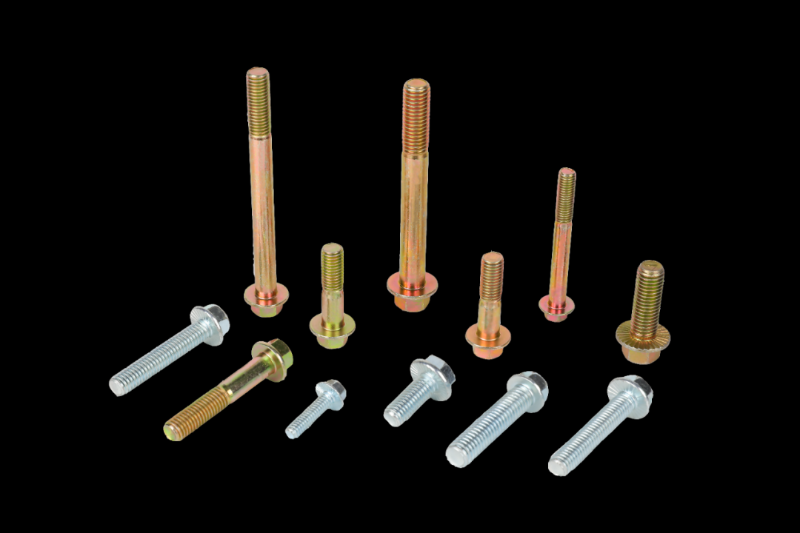

Hex flange bolt

Features: Hex flange bolt is made up of screw, nut and flange surface. One end of the screw has a thread, while the other end is connected to a flange with a larger diameter. The design of the flange surface increases the contact area, thereby enhancing the friction between the bolt and the connected object and improving the fastening effect. Nuts are usually designed in a hexagonal shape, which makes it convenient to tighten or loosen them with tools such as wrenches.

Application scenarios: Hex flange bolts because of its unique design and excellent mechanical properties, are widely used in various industrial areas, including heavy machinery, building structure, the automotive industry and aerospace, etc.

Countersunk bolt

Features: The head of the countersunk bolt is designed to be flat or slightly concave, allowing the bolt to be fully embedded into the surface of the workpiece. After installation, it is flush with the surface of the workpiece without any protruding parts.

Application scenarios: Countersunk bolts are often used in situations that require smooth surfaces, such as aircraft, building curtain walls, furniture and mechanical equipment. Because countersunk bolts do not protrude from the surface after installation, they are widely used in applications with high aesthetic requirements and no protrusions, such as wood or metal structure connections.

Disk head bolt

Feature: The head of the disk bolt is flat and slightly protruding, presenting a shape similar to a "plate". Compared with the flat round head, the head of the pan head bolt is slightly thicker and can provide greater tightening force.

Application scenarios: Head bolts are widely used in electronic products, furniture assembly, and mechanical structures, especially in those situations where high-strength fastening is required but the bolt head is not desired to protrude too much. For instance, in the connection of some metal plates or the assembly of plastic components, head bolts are very common.

Cylindrical head bolt

Features: The head shape of the cylindrical head bolt presents a cylindrical form, with a smooth surface and excellent load-bearing performance. In structural design, cylindrical head bolts are typically used in situations where there are high requirements for the appearance of the head and operational convenience.

Application scenarios: Cylindrical head bolts are commonly found in fields such as mechanical equipment, electronic products, and mold manufacturing, and are suitable for applications requiring high torque. Its smooth head makes it easy to tighten with a wrench or power tool, making it highly suitable for applications with limited space but requiring high-precision operation.

The importance of selecting bolt heads

The different shapes of bolt heads directly affect the force application mode, installation method and appearance effect of the bolts. The correct selection of the shape of the bolt head not only enhances the firmness of the connected components but also improves the safety and durability of the entire structure.

Usage effect

By choosing the appropriate shape of the bolt head based on specific scenarios, it can be ensured that the best fastening effect and aesthetic appearance are achieved during use.

Safety

Choosing an appropriate head shape can effectively reduce safety hazards, such as minimizing the risks brought by surface protrusions and enhancing the stability of connections.